Digitalization

A more digital environment means higher-quality and faster decisions, and increased transparency, collaboration and efficiency. Focus areas include:

- Monitoring and data analytics

- Remote sensing technologies

- Using real-time analytics to improve reliability and performance

- Streamlining processes with robotic process automation

Microsoft Canada

In late 2019, we announced a multi-year strategic alliance with Microsoft Canada as a part of our efforts to empower a connected and collaborative workforce, upgrade data centres, and increase analytics capabilities. Through this partnership, we are leveraging Microsoft’s full range of cloud solutions to enable the rapid deployment of new technologies to improve safety, productivity and sustainability through artificial intelligence, machine learning, enhanced automation, visualization and industrial Internet of Things.

Reliability and process safety

Advanced analytics

Suncor is implementing advanced analytics to improve personal and process safety, asset reliability, operations optimization and environmental performance. Representing a broad range of solutions, advanced analytics allows for sophisticated data mining that produces deeper insights into patterns and trends across our assets and workforce.

An example of this work is the application of analytics of process hazards analyses to support the focus on quality and prioritization of improvement opportunities. As a result, we can make faster, more proactive decisions and system changes that can prevent incidents. We expect this increased ability to make evidence-based predictions should improve reliability, reduce maintenance costs and optimize facility throughput.

Connecting frontline staff

We are connecting frontline staff to digital solutions – enabling maintenance and operations workers to create, and have access information in the field. These initiatives will enhance safety and productivity by facilitating better and immediate data-based decisions that improve our operations.

Improving safety

Remote sensing technologies

Opportunities to reduce safety risks are always a priority, and remote sensing technologies provide solutions that are quick, safe and cost-efficient.

Drones are used in our operations to assist with equipment inspection, maintenance and turnaround planning, and earthworks surveying. Their use has resulted in reduction of safety risks by decreasing worker exposure to hazardous tasks, e.g. survey crews working in remote areas, and the improvement of operations and project outcomes.

Wireless employee monitors allow us to remove obstacles that may inhibit an employee’s work and empowers us to provide faster emergency response. The devices are equipped with sophisticated gas detection monitors, which can detect hazardous levels of certain gases or solvent vapours. This allows us to identify dangerous conditions and move employees out of those areas to secure locations. The monitors are also equipped with a man down and panic button that can be used in an emergency.

Wireless employee monitors have been implemented at three sites, and the data is used to perform analytics for lower-level safety exposures and to help us identify plant integrity issues - enabling us to respond to issues, both in real time and proactively.

We are evaluating other uses for the devices. These include internal inspection of confined space, fugitive emission monitoring and leak detection.

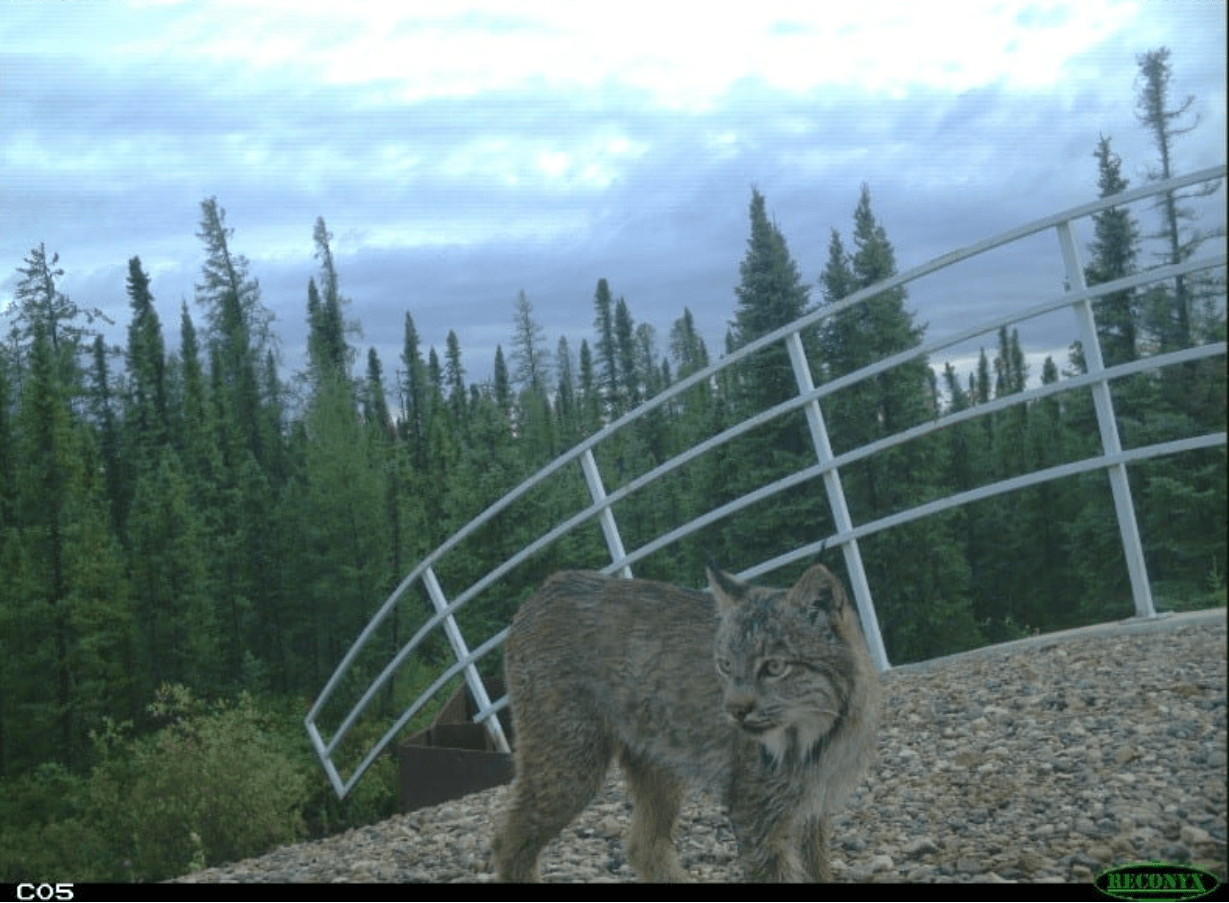

Biodiversity monitoring allow us to monitor biodiversity in and around our oil sands in situ and mining operations and reclaimed sites as per our regulatory commitments and in support of broader regional initiatives.

Due to COVID-19 pandemic restrictions, wildlife sampling in 2020 in northern Alberta was limited. However, remotely triggered wildlife cameras continued to operate and in 2020 a total of 27 wildlife species were recorded at Base Plant and Fort Hills – 18 of those species recorded in reclaimed habitats. For our in situ sites, remote cameras at Firebag recorded 13 wildlife species, and acoustic recording units recorded 26 bird species. At MacKay River, cameras recorded 15 wildlife species.

Robotic process automation

We continue to explore more opportunities using robotic process automation (RPA). To date, we have employed RPA for high-volume, rule-based and routine work. We currently have 19 bots operating across the company in Finance, Human Resources, Supply Chain and Field Logistics, Environment Health & Safety, and Maintenance and Reliability, with several more bots in development.

These new automation solutions are helping streamline our business processes, making it easier for our employees to get their jobs done so they can focus on higher-value work.

We see intelligent business process automation as a key digital enabler to deliver high-value business transformation.

Cloud-based refinery digitization

We are harnessing digital technology capabilities to help improve the safety, productivity, reliability and environmental performance of our operations. Currently, we are piloting the integration of cloud computing at the Montreal refinery to capture, analyze and provide recommendations to the facility using our existing operations process data.

While we are refining the models, the connector to and from the cloud allows us to send data to and from a database in Montreal that records the facilities’ operations data including the temperatures, pressures and volumes utilized. The cloud takes the data, models and provides recommendations for the optimized method to run the facility and help us quickly and accurately implement these recommendations at our plant operations.

To ensure the security of our data, Suncor’s cyber security team have been instrumental in piloting this project. Ensuring the success of the pilot at the Montreal refinery will allow us to replicate the functionality to digitize our other refineries.